Use

COLD & CO’s Fresh Box Plus range of isothermal packaging is used by professionals :

- delicatessens who wish to send temperature sensitive food products such as macaroons, foie gras, caviar, smoked salmon, chocolate

artisanal food producers who wish - to deliver directly their food products such as fish and shellfish, meats, delicatessen, cheeses and pastries

- companies who wish to send gourmet baskets to their customers or employees

- the medical, pharmaceutical, biotechnology and animal health sectors who wish to ship heat-sensitive health products such as vaccines, clinical trials, therapeutic products, insulin, blood derivatives

- Analytical laboratories for water and food sanitary controls within the framework of the evaluation of animal products and products of plant origin.

How it works

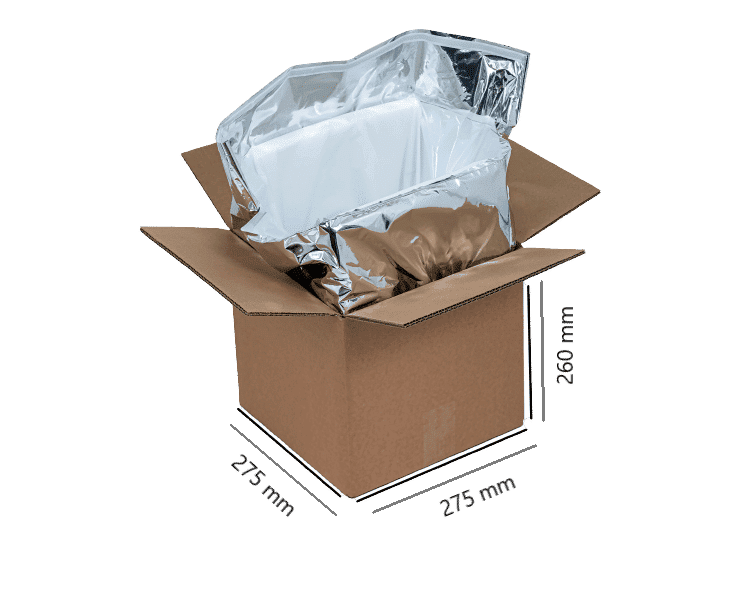

COLD & CO’s Fresh Box Plus insulated packaging consists of two components:

- an isothermal pouch delivered flat

- a shipping carton

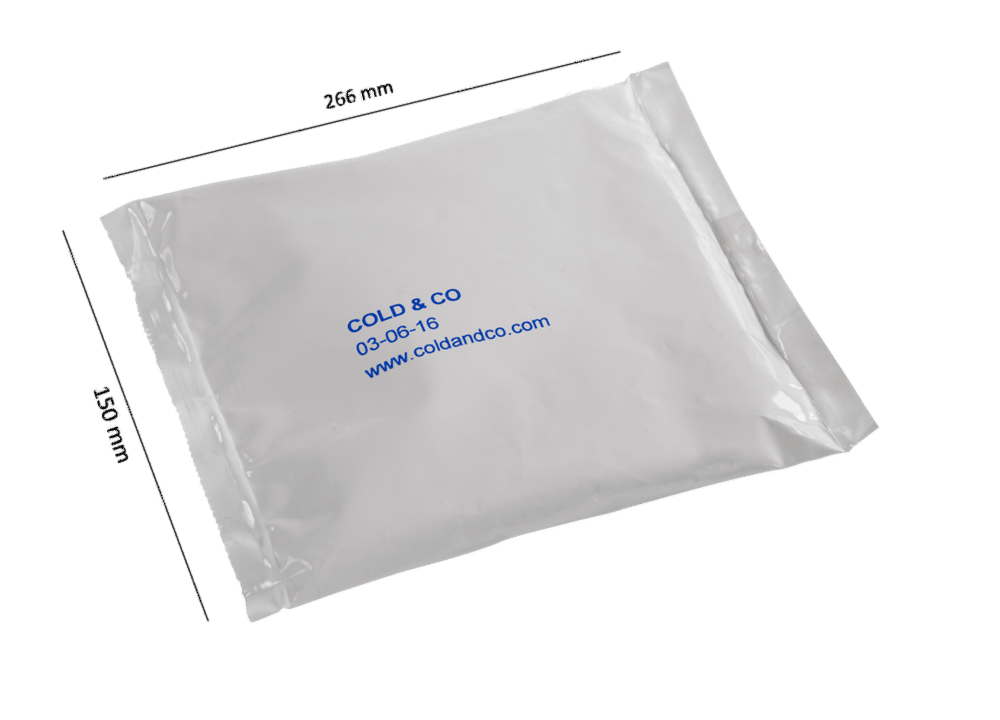

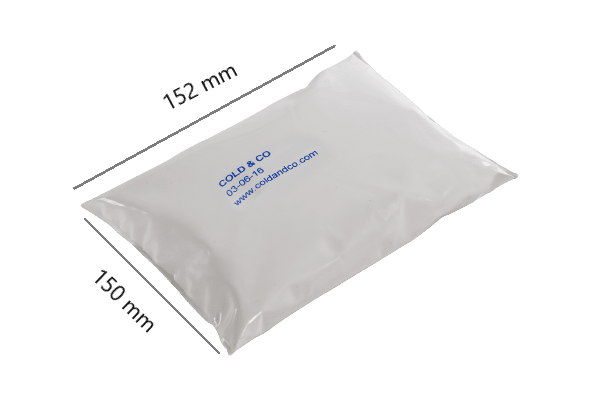

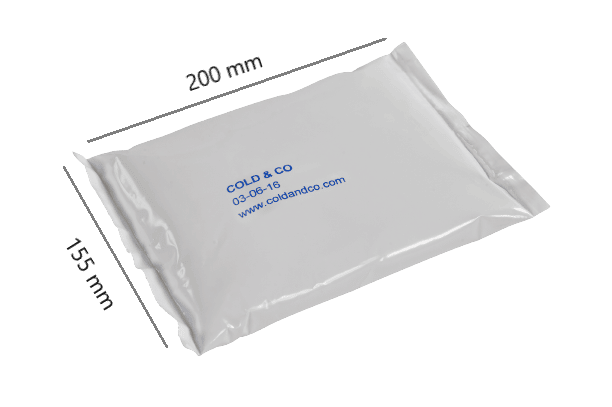

The Fresh Box Plus insulated packaging is combined with cold accumulators, called gel packs or cold gel bags. To guarantee the temperature maintenance of your heat-sensitive products, it is necessary to associate an isothermal container, which slows down the heat exchanges between the outside and the inside, with the previously frozen gel pack, which plays the role of cold engine.

(To know the right quantities and references of gel packs to associate with the Fresh Box, download our sheet « 4 steps to compose your refrigerated package » )

Interested in this product? Download the data sheet!

If you’d like more information on this product, you can download its technical sheet via the form opposite. You’ll receive your document directly by e-mail!

Constitution

COLD & CO’s Fresh Box Plus insulated packaging is made of a low density polyethylene (LDPE) double envelope lined with a 20mm thick PU foam offering a very high isothermal performance.

Delivery and assembly

The isothermal pouch is a flexible element that is delivered flat and takes shape in your cardboard box with a simple stroke of the hand. Its flexible design allows a reduction of the storage volume divided by 10, a real advantage compared to rigid polyurethane foam isothermal boxes.

Closure

COLD & CO’s Fresh Box and Fresh Box Plus insulated packaging closes like an envelope with an adhesive strip.

Waterproof

COLD & CO’s Fresh Box and Fresh Box Plus insulated packages feature a fully sealed envelope design.

Food contact

COLD & CO’s Fresh Box and Fresh Box Plus insulated packaging is certified for food contact and complies with the European directive n°2002-72 of August 6, 2002 concerning plastic materials and articles intended to come into contact with foodstuffs.

Manufacturing and environmental compatibility

Our Fresh Box Plus isothermal packaging from COLD & CO is 100% recyclable. They are manufactured in a factory on the French border which invests in offering more environmentally friendly products and whose eco-responsible actions are manifested by :

- The redevelopment of an abandoned factory to preserve green spaces

- The investment in solvent-free printing and production technologies

- Electrical autonomy through the reactivation of a hydroelectric plant

- Eliminating processes that cause air emissions and wastewater.

The result is « zero emission » production.

Any questions ?

Need additional information on a product?

Need to be accompanied to find a solution adapted to your problems related to the cold chain?

COLD & CO accompanies you and advises you to find together THE solution!

Let us contact you by filling in this contact form!