A topical challenge with the upcoming distribution of the COVID-19 vaccine

The development and distribution of a COVID-19 vaccine raises several questions about the logistics of distributing health products. The challenge concerns both the number of doses to be dispensed, the countries and manufacturing sites, but also the temperature range to which the product will be subjected. In fact, vaccines, like many health products, are subject to storage requirements under controlled temperature in order to ensure the quality of the product.

COLD & CO offers you an update on the different requirements of the cold chain of products and their associated insulated container solutions.

Temperature ranges of heat-sensitive health products

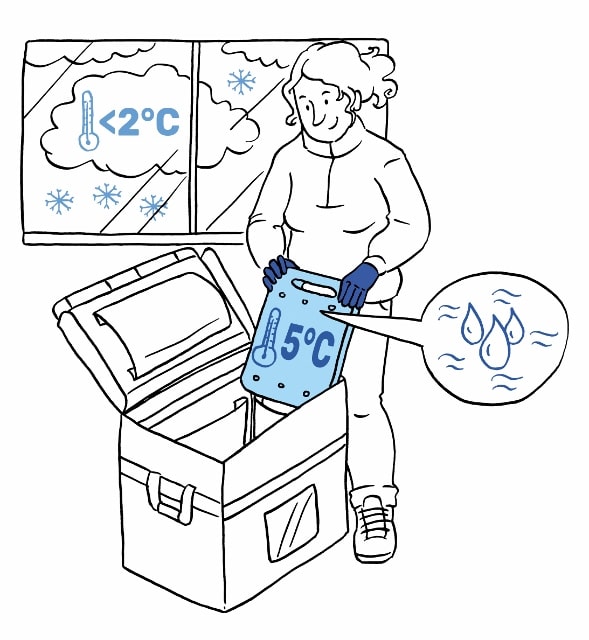

The range 2°C – 8°C

It mainly concerns vaccines, insulins, erythropoietins and new treatments resulting from biotechnology. The major difficulty is not so much to keep the products at a temperature below 8 ° C but rather to avoid cold peaks and episodes of temperature below 0 ° C which caused an immediate deterioration of the products under the effect of freezing .

The 15°C – 25°C range, often referred to as the ambient range

This is the most common range which represents the majority of heat sensitive pharmaceuticals.

The <-18 °C range, or frozen range

Here we find frozen plasmas.

Other specific ranges

Certain blood-derived products must be stored on specific shelves. Red blood cells must be stored between + 2 ° C and + 6 ° C when the blood platelet are stored between + 22 ° C and + 24 ° C.

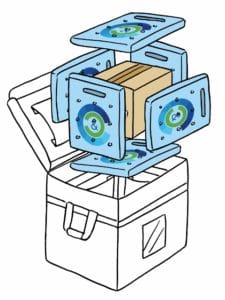

Insulated containers associated with adapted eutectic plates

To maintain the temperature of heat-sensitive health products, one solution is to combine:

- An isothermal container which will have the role of slowing down heat transfers between the external environment and the internal environment,

- With eutectic plates (also called packs or PCMs) which will compensate for heat inputs and losses by releasing the energy previously accumulated.

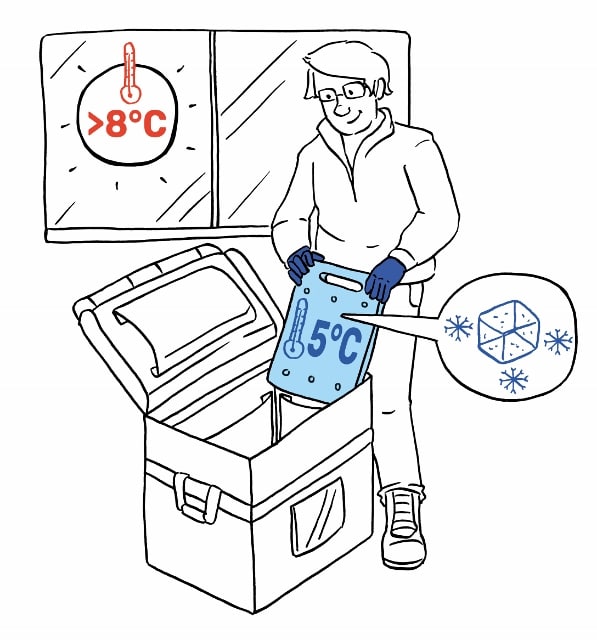

PCM+5 eutectic plates for the 2 °C – 8 °C range

Specifically designed for temperature-sensitive products in the + 2 ° C / + 8 ° C temperature range, these eutectic packs can be used whatever the season thanks to their heating and cooling modes.

In summer and off-season, use the packs at the solid state, in cooling mode. In winter, use the packs in the liquid state, in heating mode.

The eutectic liquid contained in the packs, restores cold or heat depending on its prior recharging and ensures that the temperature is maintained at + 5 ° C. ± 3 ° C.

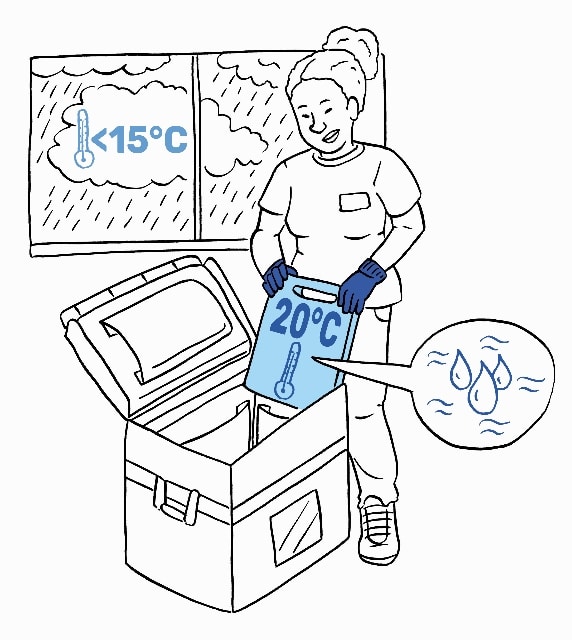

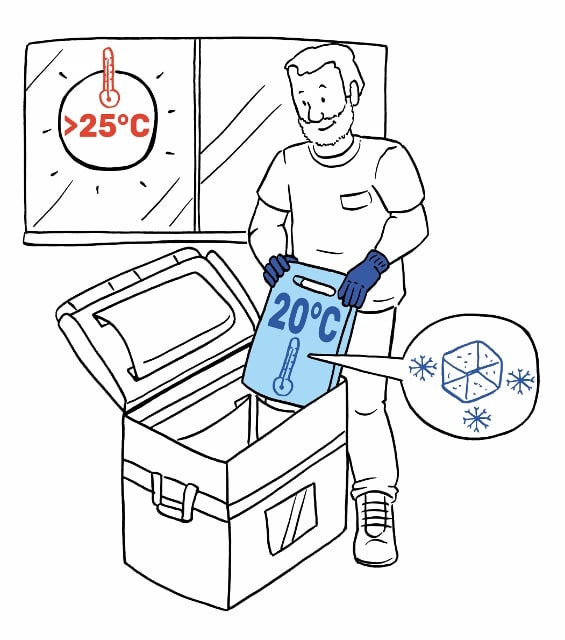

PCM+20 eutectic plates for the 15 °C – 25 °C range

The + 15 ° C / + 25 ° C range is also a complex range to manage. Thanks to the PCM + 20 pack, the hot air in summer and cold air in winter are compensated by the PCM +20. The logic is therefore the same.

In summer when the average temperature is above 25 ° C, use the packs in a solid state, in cooling mode. In winter or off-season when the temperature is on average below 15 ° C, use the packs in a liquid state, in warming mode.

Frozen eutectic plates for the <-18 °C range

To transport frozen health products, the solution is to use negative packs such as the previously frozen PCM-21. When the PCM-21 pack melts, it restores a cold to -21 ° C and thus allows you to keep your heat-sensitive products at a temperature below -18 ° C.

Specific eutectic plates for specific range

There are many eutectic liquids that provide temperatures suited to your temperature ranges. Do not hesitate to ask our teams to assist you in your choice.

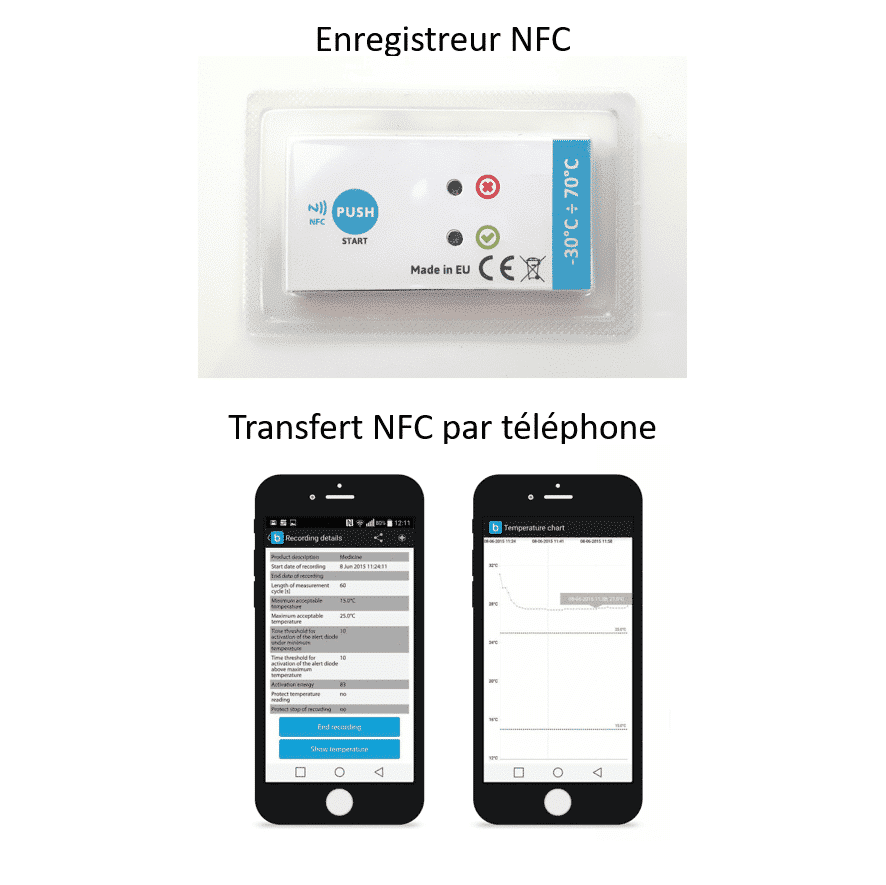

Containers qualified according to standard NF S 99-700

How to properly set up your cold chain ?

To meet your need for an insulated container or package, you should first ask yourself these 5 questions specific to your cold chain:

At COLD & Co, we have qualified our MedicalCase, MedicalCase Pharma Precision and CARE Extrême packaging for:

- target temperatures 2°C – 8°C, 15°C – 25°C and <-18 ° C;

- summer and winter outdoor temperature profiles ;

- durations from 12h to 96h ;

- volumes from 5L to 84L ;

- single-use or reusable solutions.

Do not hesitate to contact us to guide you in your choice of container adapted to your needs.

The NF S 99-700 standard

The AFNOR NF S 99-700 standard is cited as the reference to qualify the thermal performance of insulated containers and packaging for health products. This is a very comprehensive standard which specifies the measurement protocol with the number and location of the probes and which offers 21 outdoor temperature profiles from 1 to 96 hours covering the whole year.

Our solutions have been tested according to this protocol. However, in the case of a protocol specific to your operational mode, we can support you and qualify our solutions according to your temperature-sensitive products and your own outdoor temperature cycles.