Transport of the vaccine against COVID-19

Case of MedicalCase 12L

Carrying case for the anti-Covid vaccine equipped with the temperature tracking sensor of the Montpellier start-up Koovea – © François Jobard, France 3 Occitanie.

From then on, their routing becomes a real challenge for transporters: how to ensure that the cold chain is respected ? The box invented by a Montpellier start-up in 2019 makes it possible. Result: for several weeks, the company Koovea has noticed a sharp increase in its orders.

Cold and humidity have complicated the design of the box

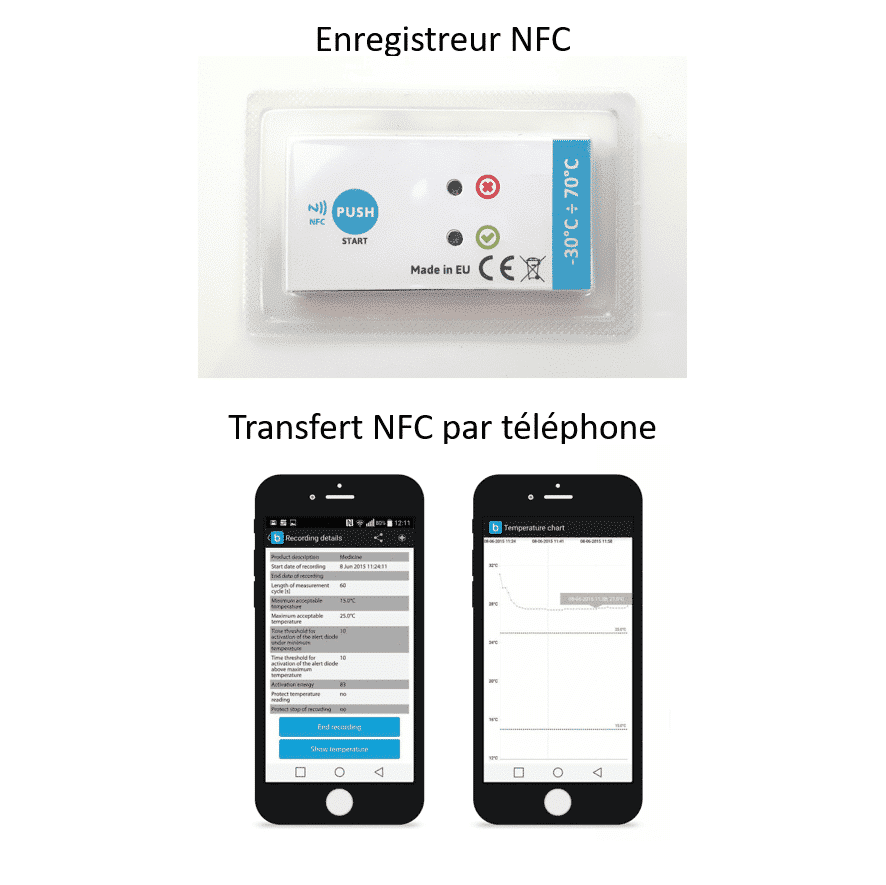

This device measures only a few centimeters. Connected and intelligent, it slips into the vaccine’s carrying case and allows the traceability of the temperature of sensitive products down to minus 200 degrees, thanks to an innovative process that gave Romain Penot, electronic engineer at Koovea, a hard time:

« The conditions of transport and storage of the vaccine are extreme: intense cold, humidity… The electronics, the plastics, the battery: all the material suffers. Yet we manage to achieve three to five years of autonomy despite the very low temperatures, but that was one of the biggest difficulties in the design. »

Romain Penot, electronic engineer at Koovea

Temperature tracking smartphone application

Because the covid-19 vaccine must be stored at minus 70 degrees, a tolerance of plus or minus 10 degrees is accepted. Beyond that, an alert is automatically sent to the carrier’s phone on which the temperatures of each refrigerated container are displayed, so that he can act to preserve the viability of the product, as explained by Yohann Caboni, director and co-founder of Koovea:

« We developed a whole system with sensors, keywords, a computer interface and an application that allows for real-time tracking of temperature, specifications and location of all Covid vaccine-type health products. »

Yohann Caboni, director and co-founder of Koovea

Activity up 10 to 20%.

Every week, 500,000 doses of vaccine are sent to France. The pace should accelerate from February.

In this context, the Montpellier-based start-up, which has customers all over the world, has seen its activity increase by 10 to 20% in recent weeks and this growth should continue.