UNDERSTANDING REFRIGERANTS

While an isothermal container is used to transport any type of product at a controlled temperature while limiting the loss of temperature between its internal temperature and the external temperature, refrigerants have a completely different purpose.

Whether we are talking about flexible or rigid eutectic gels, eutectic plates, cold blocks or the famous « ice bar », the function will always be the same: to be the engine of temperature production once inserted inside an isothermal container.

COLD & CO explains how a eutectic liquid works, what a PCM is and how to choose it, why it is necessary to associate them to an isothermal container or how to pack and use a gel or a eutectic plate.

WHAT IS A PCM ? WHAT IS AN EUTECTIC ?

PCM is the acronym for Phase Change Material.

A PCM is a material which, under the effect of temperature, changes from a solid state to a liquid state (and vice versa) while keeping the same temperature. PCMs store energy in the form of latent heat. The heat is absorbed or restored during the passage from the solid state to the liquid state.

It is this battery phenomenon that we use in passive cooling to cool an isothermal container. The heat from the environment is absorbed by the PCM when it melts and goes from the solid state to the liquid state. The result is that the isothermal container is kept cold or cooled.

PCMs can be classified into three broad categories:

ORGANIC PCM

These are kerosenes and fats. They have the advantage of offering a wide range of holding temperatures, but their latent heat per volume is a bit low.

INORGANIC PCM

These are mainly hydrated salts. Their latent heat related to the volume is important but the temperature of maintenance in temperature can be more unstable.

EUTECTIC PCM

It is a mixture of at least 2 pure bodies (organic or not). The resulting melting temperature is lower than that of the two constituent compounds. The best known eutectic is the water + salt eutectic (H20 + NaCl) often used on roads to lower the melting temperature of ice.

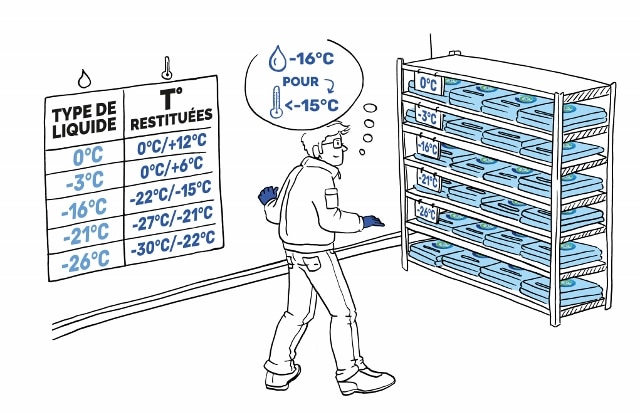

WHICH PCM TO CHOOSE ?

Choose the gel pack or eutectic plate which gives back temperatures adapted to your products. Do not hesitate to ask us for advice.

| Type of liquid | Restituted temperature | Recommended freezing temperature | Freezing time |

| PCM-26 | -30°C to -22°C | maximum -34°C | minimum 48h |

| PCM-21 | -27°C to -21°C | maximum -18°C | minimum 48h |

| PCM -3 | 0°C to +6°C | maximum -18°C | minimum 48h |

| PCM 0 | 0°C to +12°C | maximum -18°C | minimum 48h |

| PCM 5 | 2°C to 8°C | 0°C maximum during summer 12°C minimum during winter | minimum 48h |

| PCM 20 | 15°C to 25°C | 4°C maximum during summer 30°C minimum during winter | minimum 48h |

AT WHAT TEMPERATURE TO CONDITION THE EUTECTIC / PCM PLATES ?

FRESH AND FROZEN PRODUCTS

To maintain the temperature of fresh and frozen products, we recommend to condition PCM 0, PCM-3 for 24 hours at a temperature of -18°C.

For PCM-21, place them in the freezer at a minimum temperature of -26°C for 24 to 48 hours.

The PCM-26 will be conditioned at a temperature of approximately -35°C for 24 to 48 hours.

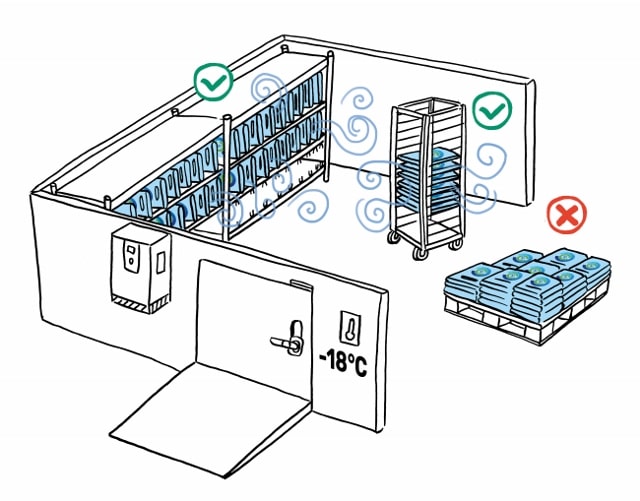

Preferably, the plates should be placed on a shelf to allow the cold air to circulate and to facilitate their cold refill.

PHARMACEUTICAL PRODUCTS RANGE 2°C TO 8°C

Specifically designed for heat-sensitive health products in the +2°C / +8°C temperature range, PCM+5 eutectic packs can be used regardless of the season thanks to their heating and cooling modes.

If the outside temperature is on average >8°C, use the packs in a solid state, in cooling mode.

We recommend to load them beforehand for at least 24 hours between -15°C and -30°C in order to obtain a solid state. To avoid cold spikes, stabilize the plates between -2°C and 0°C before insertion into the pack by leaving them at room temperature for 30 minutes (for freezing at -15°C) and 45 minutes (for freezing at -30°C).

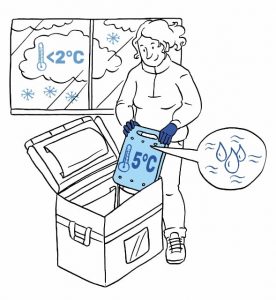

If the outside temperature is on average <2°C, use the packs in liquid state, in warming mode.

We recommend to load them beforehand for at least 24h at a temperature higher than 12°C in order to obtain a liquid state. Then, 12h before introduction in the pack, stabilize the plates at +5°C.

PHARMACEUTICAL PRODUCTS RANGE 15°C TO 25°C

Specifically designed for heat-sensitive health products in the +15°C / +25°C temperature range, PCM+20 eutectic packs can be used regardless of the season thanks to their heating and cooling modes.

If the outside temperature is on average >25°C, use the packs in a solid state, in cooling mode.

We recommend to load them beforehand for at least 48h at a temperature below 4°C in order to obtain a solid state. Before insertion into the pack, stabilize the plates at room temperature for 30 to 45 minutes.

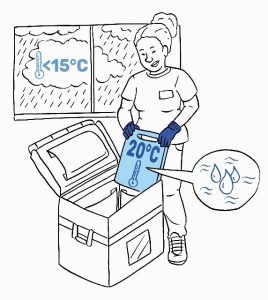

If the outside temperature is on average <2°C, use the packs in liquid state, in warming mode.

We recommend to load them beforehand for at least 24h at a temperature higher than 12°C in order to obtain a liquid state. Then, 12h before introduction in the pack, stabilize the plates at +5°C.

WHY COMBINE AN ISOTHERMAL CONTAINER WITH A COLD SUPPLY ?

As we have seen previously, heat is an energy that is transferred from a hot body to a cold body. The exchange does not stop until the two bodies are in equilibrium at the same temperature.

An isothermal material will slow down these heat inputs until the internal and external environments are at the same temperature. An isothermal container alone cannot maintain the desired temperature stability. A cold supply is necessary: active cold, passive cold or cryogenic cold…

SOFT GELS, ABSORBENT GELS, RIGID GELS, EUTECTIC PLATES, ... HOW TO FIND YOUR WAY ?

PCM, eutectics, gels are packaged in different forms. We present you the most common ones to choose according to your needs.

- Soft gels, also called gel packs, are flexible bags made of an opaque or transparent film containing the eutectic or PCM in gelled form. These bags are lighter and more economical than a rigid gel because of the economy of the rigid shell. However, they must be frozen flat to give them a homogeneous shape after freezing.

- Absorbent gels are soft gels with a film of absorbent material in the pocket. Condensation and water droplets that appear when melting conventional gels are absorbed by this woven coating. We recommend this liner to protect heat-sensitive products from moisture. As with conventional soft gels, they should be frozen flat to give them a uniform shape after freezing.

- Rigid gels have a rigid outer shell often made of high density polyethylene (HDPE) to resist impact, compression and puncture. These shells are then filled with the desired eutectic fluid or PCM and closed with a crimped cap. They are available in different sizes and weights ranging from 250g to 1kg.

- Eutectic plates have the same characteristics as rigid gels. With weights ranging from 2kg to 4kg, eutectic plates come in more standardized sizes called gastronorm. The most common sizes are :

> GN 1/1 trays with dimensions 530 x 325 x 30 mm

> GN 1/2 trays with dimensions 325 x 265 x 30 mm

HOW AND FOR HOW LONG SHOULD EUTECTIC PLATES BE CONDITIONED ?

We recommend a minimum conditioning time of 48 hours for PCMs. A PCM is fully conditioned when all the liquid in the PCM has become solid. The correct freezing of the cold accumulators can be verified by simply shaking the gels or plates. If we perceive a liquid or semi-liquid state, the eutectic solution is not fully charged.

To speed up the packaging, the eutectic plates must be separated from each other inside the freezing chamber. Stacked storage or storage in cardboard boxes or pallets prevents the circulation of cold and increases the freezing time considerably. It is then necessary to count up to 1 week to freeze the eutectic plates to the core.

To facilitate the packaging of eutectic plates and PCM, we recommend the use of plate distribution carts or shelves to organize and disperse the eutectic plates.

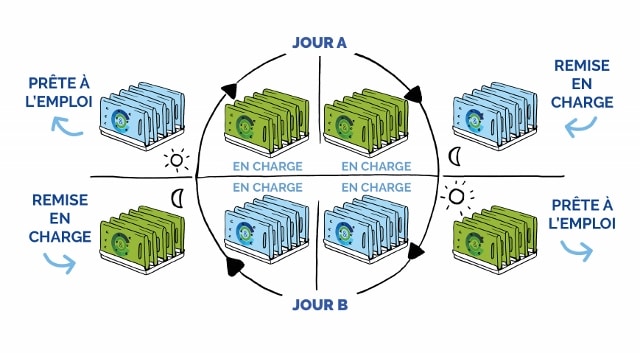

To ensure that the plates are always available, a double set of eutectic plates allows the implementation of a plate rotation system: when one set of plates is used, another set is refilled.