Cold-chain solutions company COLD & CO has teamed up with Blulog to provide a system for tracking temperatures in thermal, lightweight containers during the last mile of food delivery to customers.

RFID Journal, Jul 03, 2019

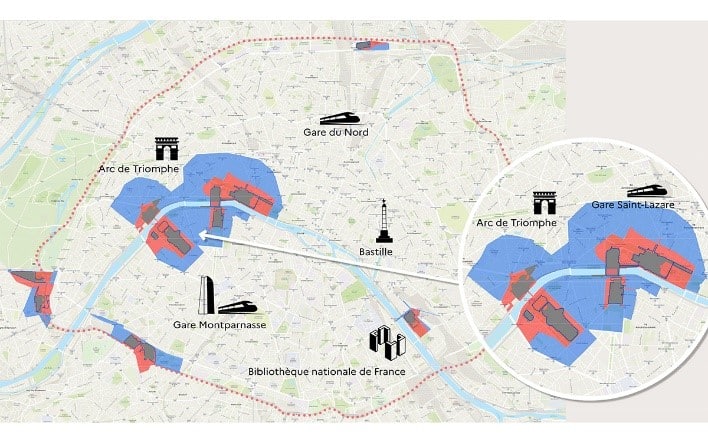

Several European delivery companies are striving to make the last mile of food delivery fast and ecological. Companies like Stuart Logistics provide bicycle-, scooter- or electric vehicle-based delivery of meals or groceries to individuals in Paris and other urban areas.

To ensure that the temperature of food being delivered never ventures outside of acceptable thresholds, Stuart is employing a Near Field Communication (NFC)-enabled solution provided by COLD & CO, using Blulog‘s NFC dataloggers. Stuart provides delivery services in 69 cities for more than 2,000 business clients, such as retailers and restaurants. Its delivery personnel utilize electric Nissan eNV 200 vehicles to pick up and deliver goods to customers in their homes or offices. French-Belgian firm COLD & CO has been providing delivery companies with thermal boxes, packaging and coolers for several years, which are typically used in France, Benelux (Belgium, Luxembourg and the Netherlands) and Switzerland. The containers are made of a washable, lightweight nylon material similar to that used to make backpacks. The partnership with Blulog adds a technological feature, however: mobile temperature tracking.

Blulog and COLD & CO had previously built a solution for the transportation of salmon that ensures product is never exposed to unsafe temperature levels, says Jeremy Laurens, Blulog’s cofounder and CEO. Delivery companies like Stuart Logistics are using the system in a similar way, utilizing reusable nylon bags to carry the food. In some cases, the food is picked up hot from a restaurant or café and needs to be delivered quickly so that it retains its heat. In other scenarios, the food is cold and picked up from stores, and must stay within a specific threshold to maintain its freshness.

« COLD & CO commits to offer efficient solutions with adequate isolation and refrigeration, »‘ says Adrien Lehideux, the company’s CEO. The firm seeks to follow temperature requirements based on minimum and maximum temperature ranges, as indicated by food manufacturers and by legislation.That, Lehideux says, is where the company benefits from the Blulog technology « bringing traceability and guarantee of the correct temperature. »

The system consists of COLD & CO‘s CarryTemp XL6 cooler with Blulog’s built-in NFC 13.56 MHz datalogger, which is compliant with the ISO 14443 standard. The thermal container comes with a coolant, in the case of perishable cold goods. The company wants to trace the amount of time the product remains in transit, as well as the product’s temperature range, and to link that data with the actual product being delivered and its location.

When a delivery person picks up goods, that individual uses his or her mobile phone to scan the NFC datalogger. The phone’s built-in NFC reader captures the unique ID number of the datalogger’s tag. When the order is delivered to the customer, the driver again scans the datalogger tag and displays the collected data for the customer in order to indicate the temperature at which the product has been maintained. That data, along with the GPS location, is forwarded to the cloud-based software to create a record of that delivery. Once the delivery is complete, the container is cleaned and returned to participating businesses for reuse.

NFC Tracks Passive Refrigeration for Low-Carbon-Footprint Deliveries

Cold-chain solutions company Cold&Co has teamed up with Blulog to provide a system for tracking temperatures in thermal, lightweight containers during the last mile of food delivery to customers.