COLD & CO presents its logistical innovations for the transport of heat-sensitive products in the October 2019 issue of Informations Entreprise.

The cold chain represents about 15% of transport flows. Whether pharmaceutical or food products are transported internationally, regionally or locally, temperature-sensitive goods flows require a guarantee that temperatures are respected from the first to the last kilometer. The increasing development of home deliveries, new last mile logistics models and the multiplication of delivery points require temperature-controlled transport to adapt. Adrien Lehideux, Managing Director of Cold&Co, a provider of isothermal solutions in passive refrigeration, provides an update on these developments.

Transportation of fresh and frozen food products

In France, the transport of fresh food products is subject to the requirements of the Agreement on the Transport of Perishable Foodstuffs (ATP) relating to international transport and the equipment to be used for such transport. This United Nations agreement, which came into force in 1976 and was signed by 48 countries, sets out the isothermal and refrigeration performance requirements for transport under controlled temperature (refrigerated transport). This obligation can be waived for transports of less than 80 km without breaking the load, i.e. without opening the doors of the refrigerated enclosure. In the city center, in the case of the distribution of fresh products in multiple points, the deliveries are carried out with loss of load. The last mile cold chain must then be ATP certified using sufficiently insulating solutions with good refrigeration capacity.

Transportation of heat-sensitive health products

Similarly, in the healthcare sector, Good Distribution Practices (GDPs) set out quality management systems to ensure the proper preservation of temperature-sensitive pharmaceutical products throughout the supply chain, from the delivery of raw materials to manufacturing plants to the shipment of finished medicines to pharmacies and the end user.

The need is mainly spread over 3 temperature ranges: ambient (between 15 and 25°C), fresh (between 2°C and 8°C) and frozen (below -18°C).

Last mile logistics in the city center

At the same time, the strong development of distribution in city centers is pushing large cities to implement environmental policies for urban distribution: improving air quality, reducing noise pollution, relieving congestion in urban areas. New eco-responsible modes of transport are being developed: clean vehicles, utility bicycles, automatic lockers, multimodal transport, urban hubs, collaborative delivery services, etc.

What about the cold chain? Traditional active cold transport (i.e. a box powered by a mechanical cooling unit) cannot meet these new delivery requirements because it consumes fossil fuels and generates noise pollution. In the case of an electric refrigerated van with a cooling unit, it is the autonomy of the vehicle’s battery that is impacted.

Isothermal solutions in passive cooling

One answer to this problem is to create, for each type of flow, a high-performance container, if necessary ATP certified, isothermal and refrigerated in passive cold, i.e. operating autonomously without consuming fuel or electricity during delivery. Depending on the type of transport (air, road, bicycle or pedestrian), there is an adapted solution.

In response to this market, COLD & CO has designed a range of light refrigerated containers that can convert a dry vehicle into a « bi-temperature » or even tri-temperature vehicle. Whether the vehicle is conventional or electric, the COLD & CO container is inserted inside the rear trunk or side door and provides flexibility by coupling a delivery of dry goods with fresh or frozen goods.

Refrigeration is provided by « eutectic » plates. These jelly water briquettes, designed and tested in COLD & CO’s laboratories, guarantee the temperature defined by the customer. The COLD & CO container is a real convertible solution, easy to handle, which also solves the problem of unavailability of refrigerated utility vehicles. The shortage of refrigerated vehicles during peak delivery periods can be a real headache for supply chain actors. The economic dependence on external fleets has a financial and commercial cost. Thanks to an autonomous refrigerated container, logisticians can adapt their existing fleet of vehicles and can position themselves on multiple delivery tenders. With its positioning in cold chain consulting and custom design of refrigerated equipment, COLD & CO has also adapted its range for 2 and 3-wheel deliveries. The last mile in the cold chain is therefore available for delivery by electric scooter and cargo bike!

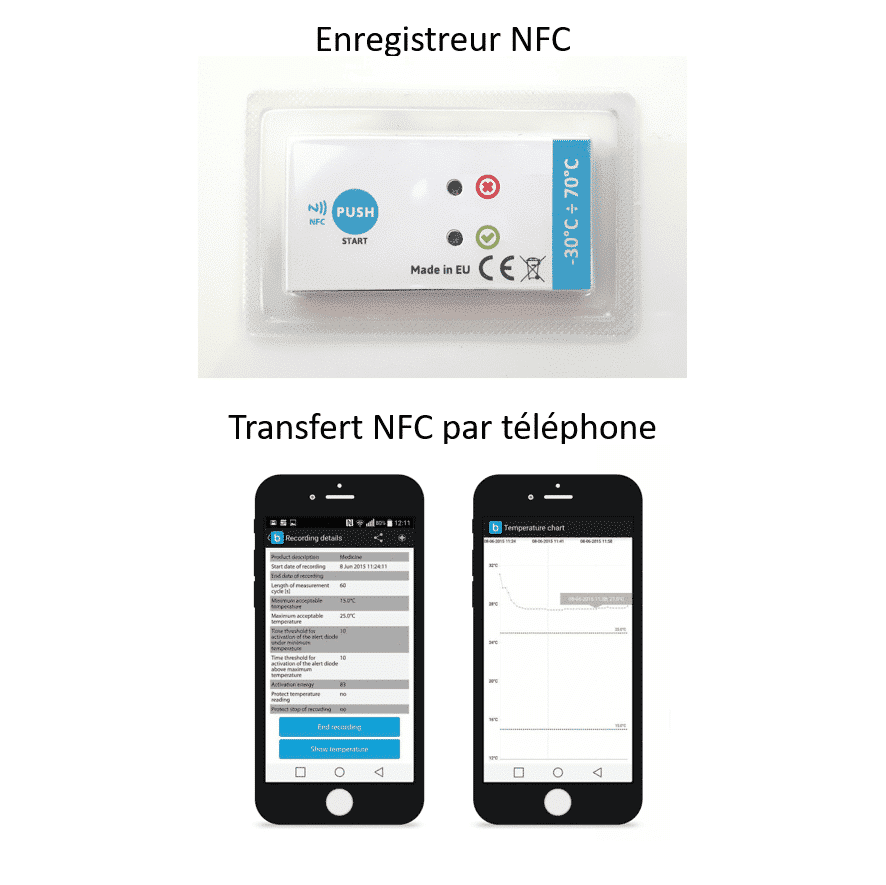

Heat-sensitive products traced and bound

Thermal traceability of heat-sensitive health or food products is essential. To do this, temperature sensors record and transmit the temperature of containers connected to the computer system using Bluetooth, RFID or NFC technologies. The client is thus warned by alert in the event of a poorly closed container or a delay that lowers the temperature threshold.

Thus, for each temperature range, each logistic flow, each delivery mode, a solution of bags, coolers, covers, crates or refrigerated containers in passive cold allows to answer the needs of a certified, connected, environmental, operational and flexible cold chain with a range of useful volumes going from 1L to 2,5m3. For a last mile logistics with a controlled cold chain, COLD & CO accompanies all its customers and designs in close collaboration with them an operational solution precisely sized.